Japanese Companies’ Actions Regarding the Major Trends of the New Industrial Revolution

KOJIMA Akira, Chairman of World Trade Center Tokyo, Inc., Member, Board of Trustees of the National Graduate Institute for Policy Studies

Displays of books entitled Industrie 4.0, IoT Revolution, New Machine Age and Artificial Intelligence can be seen in special sections in bookstores. The Revised Japan Revitalization Strategy 2015: Revolution in Productivity by Investment in the Future, which the Japanese government announced in June 2015, hammers out the government’s commitment to accelerating challenges toward a new era and the Fourth Industrial Revolution in the general introduction. The strategy emphasizes, “The changes by IoT, big data and artificial intelligence are expected to progress at greater speed and with a greater impact than ever before in history, but our country, which lags slightly behind, has no time or margin for trial and error.” Although there are active discussions about this issue to a certain extent, it appears that overall, Japan lacks a keen awareness of being “one lap behind” this new trend. The revitalization strategy notes that Japan “lags slightly behind,” but the reality of Japan’s lagging behind is far more serious.

The drivers of changes are information technology (IT) and the Internet. The year 1995 after the burst of the bubble economy in Japan is considered to be the “milestone year of the Internet” in the United States. The IT boom underwent some adjustments, including the collapse of the so-called IT bubble in 2002, but the use of IT and the Internet in the United States has been expanding and developing over the period of time up until now. The noticeable emergence of the major IT companies referred to as GAFA is symbolic: G for Google (established in 1998), A for Apple (established in 1976), F for Facebook (established in 2004) and A for Amazon (established in 1994). The total of the market capitalizations of these four companies adds up to hundreds of tens of trillions of yen. Three of these companies are emerging large corporations that rose while Japan was mired in pessimism and passivity, lamenting “the lost decade and the lost two decades.”

Fundamentally speaking, IT and the Internet do not produce values and profits by themselves. They are called enabling technologies, and knowing how to use them is the key to getting the most out of them. IT was initially called ICT in other countries, with the word communication in the middle, but Japan had a poor sense of this concept of C. This resulted in people paying more attention to the aspect of IT hardware rather than how to fully utilize it. Just as IBM broke away from hardware production and grew into a company with a focus on the software business, including business solutions services, by carrying out organizational change, industries and companies have been in the process of undergoing technical paradigm shifts for growth and added value.

The history of progress in manufacturing

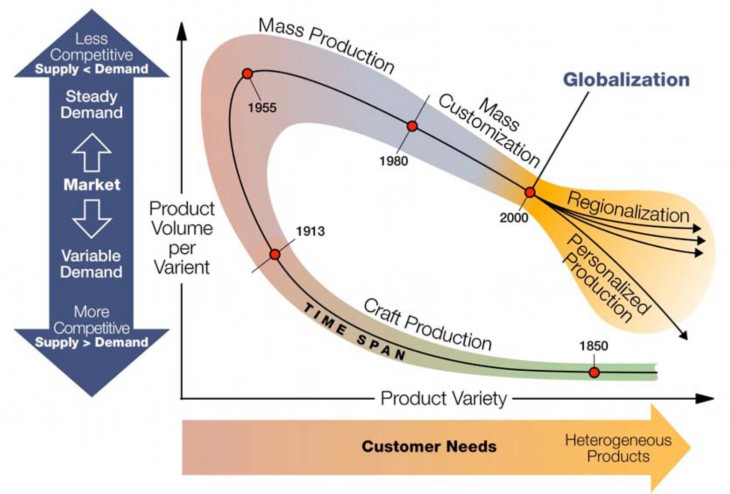

The illustration below is an awareness-raising graphical image of the historical transformation of manufacturing compiled by the Fraunhofer-Gesellschaft, a participant in the Industrie 4.0 platform, which Professor Yoram Koren from the University of Michigan discussed in The Global Manufacturing Revolution in 2010.

| The drivers to new paradigms are market and society needs |

|

| Source: Yoram Koren “The Global Manufacturing Revolution” http://adrge.engin.umich.edu/wp-content/uploads/sites/50/2013/08/12pgbook.pdf |

The vertical axis indicates product volume and the horizontal axis indicates customer needs, with more heterogeneous products to the right. The mainstream manufacturing model in the nineteenth century was the production of heterogeneous products by manual labor, and the product volume was small. The year 1913 was the threshold that marked the start of the mass production of the Model T Ford by belt conveyor in the United States. This prompted an industrial shift to the mass production of a small number of products in pursuit of economies of scale in major countries. Subsequently, major countries shifted to the small-number production of heterogeneous products in the 1980s, and then to the Internet-based model of responding to personalized needs with a focus on individual preferences with an increasing diversification of values in the twenty-first century.

Germany quickly recognized the significance of this personalized needs system, which led to the creation of Industrie 4.0. This concept is intended to realize the small-number production of heterogeneous products at the same cost as the mass production of a small number of products through the digitization of factory operations. Germany calls this “mass customization.”

Germany’s sense of crisis

Germany is currently said to be a dominant euro zone winner, but it in the late 1990s it was referred to as “a sick country in Europe,” suffering from low growth, high unemployment and current account deficits. One factor in Germany’s becoming a dominant euro zone winner was the significant devaluation of its exchange rate due to the introduction of the euro as a single currency compared with the era of the Deutsche Mark. Another factor was the comprehensive reform carried out by the Schröder administration (1998–2005). (“Learning from European Competitiveness: Focusing on Schröder’s Reforms in Germany,” the April 2015 Report of the Japan Association of Corporate Executives, No. 2015-3)

At the time when Schröder’s reforms were gradually beginning to bear fruit, the Merkel administration formulated an action plan for the High-Tech Strategy 2020 in November 2011, and announced the policy of promoting Industrie 4.0. In March 2013, the Fourth Industrial Revolution (Industrie 4.0) was announced as a major national project based on cooperation between the government, companies, universities and other research institutes. This initiative was joined by Siemens, Bosch, Daimler, BMW and SAP, and the Industrie 4.0 Platform was established.

The German government looks at the history of the Industrial Revolutions in the following way. The First Industrial Revolution was driven by steam engines and hydroelectric power that originated in the United Kingdom in the late eighteenth century. The Second Industrial Revolution was symbolized by the utilization of electric power and production by belt conveyer that originated in the United States in the early twentieth century. The Third Industrial Revolution involved the widespread penetration of electronics, IT utilization, automated production, industrial robots and FA equipment that began in the early 1970s. The Fourth Industrial Revolution, which Germany is currently seeking to promote, aims to create “smart factories” called cyber physical systems (CPS) by connecting factories via the Internet and utilizing artificial intelligence.

Behind these moves being made by Germany is the country’s sense of crisis caused by the dramatic and accelerated changes in German manufacturing business environments: (1) the increase in labor and energy costs; (2) the rapid rise of emerging economies in Asia and Eastern Europe and increasing competition with the United States; (3) increasing pressure

toward the customized creation of high added value and the rapid marketing of new products triggered by the diversification of market needs; and (4) the growing need to pursue a paradigm shift by utilizing ICT and IoT for the manufacturing sector amid the widespread use of ICT and the Internet.

Mutual approach of the United States and Germany

In March 2014, a year after Germany had unveiled Industrie 4.0 as a major national project, five U.S. companies — General Electric (GE), IBM, Intel, Cisco System and A&T — launched the Industrial Internet Consortium (IIC) with the aim of creating a new industrial revolution by not only realizing a smart manufacturing industry but also by making the entire industry smart. This consortium is currently joined by about 180 leading companies.

What is noticeable is that these 180 companies include Siemens, Bosch, SAP and other German companies that are part of the Industrie 4.0 project, Swiss ABB and other non-U.S. companies. These four particular companies joined the framework from January to March 2015. Chinese and South Korean companies are also showing interest in the IIC.

As mentioned above, books about Industrie 4.0 and IoT were published one after another in Japan this year, and there is increasing public interest in Industrie 4.0 and IoT. However, corporate managers appear not to recognize the urgent need to show interest in these things.

An expert has expressed concerns, saying, “Japan, which achieved success in the Third Industrial Revolution, may continue to be excessively confident in its manufacturing industry. Current corporate managers experienced and contributed to the success during the Third Industrial Revolution, and I suspect that their awareness of these experiences has resulted in their underestimation of the movement of a new industrial revolution.”

In fact, some people say that Industrie 4.0 is what Japan has already done in the manufacturing industry, and that it will be an extension of it in the future as well. Of course, Japan saw Komatsu gain high evaluations both domestically and internationally in recognition of its IoT-based efforts for construction machinery and the development of an outstanding business model.

Unlike the case of Komatsu, however, many U.S. and German companies, including mutually competing ones, are seeking to collaborate in promoting a revolution, not only in the manufacturing industry but also in the service industry and other industrial sectors in the United States.

Some people claim that this move is merely an “advertising balloon” for IT companies to attract customers and expand markets.

The second machine age

A book entitled The Second Machine Age, which was published in 2014, was a focus of discussion at the World Economic Forum’s annual meeting in Davos, Switzerland, in January 2015. (The Japanese translation of the book is entitled Za sekando mashin eiji, published by Nikkei Business Publications in 2015.) The book was written by two professors at the Massachusetts Institute of Technology. Professor Okazaki Tetsuji of the University of Tokyo says, “The book notes that the current technological progress in process is characterized by the exponentially greater performance of computers and other related devices, their digitization and combination-based innovation, and that the combination of these three characteristics is inviting the arrival of a new machine age.”

At the start of the book, the authors introduce the astonishing impact of their experience of driving an automatically piloted car developed by Google in 2012. In October 2010, Google announced its successful test drive of a completely unmanned car on ordinary streets and expressways in the United States. By the summer of 2012, when the two authors experienced driving Google’s automatically piloted car, there were just two accidents while a group of Google cars were covering a total of 200,000 kilometers by automatic pilot. One of the accidents occurred when the automatic pilot mode was accidentally switched to the human pilot mode and the other occurred because while the Google car was stopping at a red light, it was hit by a human-piloted car just behind it. Subsequently, test drives continue to be carried out without incident.

When I was reading the book, I was struck by the idea that the largest future competitor of Toyota could be Google or new market participants from an area that is currently unrelated to car production. I strongly felt that we were experiencing the critical process of a technological paradigm shift.

The great initial phase of innovation

There is no time or room left for Japan to look back on its past achievements and rest on its laurels. Even if Japan thinks of its environmental technologies as being the best in the world, the rest of the world is rapidly catching up. Meanwhile, Japan has been less willing to take on challenges in the new technological era than some other countries, at least until recently.

Economist Musha Ryoji, president of Musha Research Co., Ltd., claims that the great initial phase of innovation will occur from now on, and calls for Japan to actively take on challenges in the new era. Some people are concerned that as the machine age progresses, more workplaces will be lost. Recently, a book entitled Fifty Jobs that Will Disappear in the Next Twenty Years attracted public attention. However, Musha says, “What is decisively lacking in this book is the other perspective, that is, the perspective of fifty new jobs that will be created in the next twenty years.” He adds, “Computers have deprived people of a considerable number of jobs. Many tasks, including manually operated accounting transactions, sales data processing and calculations by abacus, have been taken over by machines. But there has been no overall increase in unemployment during the last thirty years, and this is because new jobs were created as replacements.”

Short-term economic observations based on previous-term and previous-year comparisons are important, but it is also essential to gain a broader perspective of the changing times.

Translated from an original article in Japanese written for Discuss Japan. [December 2015]